The AccuGrade Grade Control System brings to the customer an increase in productivity by up to 40 percent while reducing their site costs dramatically. The revolutionary Caterpillar® solution is factory integrated, sensor-independent, and features a suite of products, which includes cross slope, sonic, laser, GPS, and ATS technology.

We understand that productivity and our customer’s bottom line depend on moving material accurately, quickly, and safely the first time. Maintaining consistent grade is difficult, labor intensive, and challenging for even the most experienced operators. By combining digital design data, in-cab operator guidance features, and automatic blade controls, our AccuGrade Grade Control System actually enhances grading accuracy and virtually eliminates the need for survey stakes.

ACCUGRADE READY OPTION (ARO)

The ARO machine simplifies system installation and reduces machine downtime. The AccuGrade system is designed and integrated into the machine systems and controls to optimize performance and reliability.

ACCUGRADE CROSS SLOPE

ACCUGRADE™ Cross Slope is a grade control system designed to control surface cross slope. Machine-mounted sensors are used to calculate necessary blade slope positioning to achieve desired cross slope of the surface. The system makes automatic adjustments to the left or right lift cylinder, typically performed by the operator.

click to learn moreACCUGRADE™ Cross Slope delivers all the information the operator needs to quickly and easily spread or cut material at the correct cross slope to the in-cab display. The operator can select which side of the blade to control automatically and swap direction on the return pass without readjusting the settings. Elevation is controlled manually by matching grade, or automatically by adding an elevation control device.

Cross Slope System. The basic cross slope system automatically controls the slope of the blade to maintain desired surface cross slope.

Cross Slope with Elevation Control. ACCUGRADE™ Cross Slope can be combined with one or more of the AccuGrade elevation control technologies, such as ACCUGRADE™ Sonic, ACCUGRADE™ Laser, ACCUGRADE™ GPS, or ACCUGRADE™ ATS for automatic control of elevation and cross slope.

AccuGrade delivers a wide range of customer benefits designed to: increase operator efficiency and productivity, improve accuracy, reduce material costs, reduce surveying and labor costs, and lower overall operating costs.

AccuGrade delivers a wide range of customer benefits designed to: increase operator efficiency and productivity, improve accuracy, reduce material costs, reduce surveying and labor costs, and lower overall operating costs.

ACCUGRADE ATS

AccuGrade™ ATS is a high accuracy dynamic tracking system that uses an Advanced Tracking Sensor (ATS) to track a machine and monitor blade positioning. An ATS instrument on the work site is used to track a target, which is mounted on the blade of the machine, to determine precise 3D positioning.

Active target technology allows the system to reliably lock onto and track the intended target. This ensures the correct machine is being tracked and eliminates false lock-ons to other active machine targets, survey crews, or reflective surfaces. Built-in search intelligence allows the system to quickly search for and find the target when the lock is lost due to a passing vehicle or other interruption.

The ATS instrument continuously measures the target’s position and transmits real-time positioning data to the operator via the in-cab display, which shows the exact position of the blade in relation to the design. The system combines the position of the target with the known position of the instrument, machine measurements and sensor outputs to calculate precise positioning of the blade tips. The system uses the positioning data to calculate desired elevation and cross slope. Cut and fill values are computed by comparing the position of the blade with the design file. The system makes automatic blade adjustments typically performed by the operator and provides automatic blade control to one or both cutting edge tips.

AccuGrade™ ATS puts the information the operator needs to complete the job in the cab. The operator simply steers the machine to achieve fine grade surfaces with high-precision accuracy.

ACCUGRADE GPS

Current earthmoving and fine grading processes are labor intensive and dependent on manpower and instruments. Maintaining consistent grade between stakes is challenging, even for experienced operators. ACCUGRADE™ GPS reduces labor requirements and helps operators work to the design plan by accurately cutting, filling, and reducing material cost.

The ACCUGRADE™ GPS control system is the best solution when the construction site involves contours, rather than single or dual slope planes. The ACCUGRADE™ 3D system uses GPS technology to compare the blade position to a three-dimensional computerized site plan and signals the operator or hydraulic system to raise or lower the blade to achieve the design requirements.

Advanced GPS technology solutions move the design plan to the cab for greater operator control, increased accuracy, higher productivity and lower operating costs.

The ACCUGRADE™ GPS Grade Control System is a high technology machine control and guidance system that allows dozer operators to grade with increased accuracy, without the need for survey stakes. Digital design data, in-cab operator guidance features and automatic blade controls help the operator achieve grade faster, meaning higher productivity, lower operating costs, and greater profitability.

ACCUGRADE™ GPS is designed for a wide range of construction earthwork applications, from bulk clearing with high production rates to finish grading with tight tolerances.

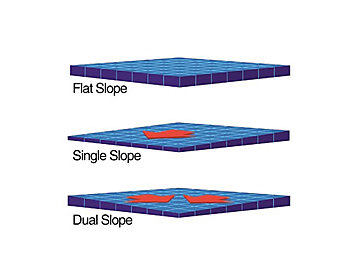

Flat, single and dual sloping planar designs, such as building pads, parking lots, roads and highways, can be created on-board the machine using the ACCUGRADE™ GPS system. Complex 3D designs, such as golf courses and roads with super elevations, can be created in the office by design engineers and loaded onto the system via a compact flash card.

Fine grade with greater accuracy and control with AccuGrade technology solutions for motor graders. AccuGrade begins with the basic 2D cross slope system. System flexibility allows elevation control to be combined with cross slope control to meet a wide range of site-specific grade requirements.

Fine grade with greater accuracy and control with AccuGrade technology solutions for motor graders. AccuGrade begins with the basic 2D cross slope system. System flexibility allows elevation control to be combined with cross slope control to meet a wide range of site-specific grade requirements.

FEATURES & BENEFITS

ACCUGRADE SONIC

AccuGrade™ Sonic is a grade control system designed to control surface elevation. The sonic system uses an ultrasonic sensor to maintain the blade at the same relative vertical distance to an external reference, such as a string line or curb and gutter.

The system makes automatic elevation adjustments typically performed by the operator when in cross slope only control. The operator simply steers the machine to maintain the sensor over the external reference.

- Single Sonic System – when combined with AccuGrade Cross Slope, the single system provides automatic blade adjustments to one side of the blade for automatic control of elevation and cross slope.

- Dual Sonic System – when two sonic sensors are used, the system provides automatic elevation control to either side of the blade. The system typically uses only one sensor at a time. This allows the operator to control which side of the blade to control and change direction without relocating sensors.

ACCUGRADE LASER

Caterpillar is helping customers revolutionize the way they move dirt with new technology solutions for earthmoving machines. Solutions that provide greater accuracy, higher productivity, lower operating costs, and more profitability.

The AccuGrade™ Laser Grade Control System is a high technology earthmoving tool that allows dozer operators to grade and fill with increased accuracy without the use of traditional stakes or grade checkers. Using advanced laser technology, machine-mounted components and an off-board laser transmitter, this state-of-the-art machine control system provides precise elevation information on an in-cab display to achieve accurate blade positioning. As a result, operators can improve their efficiency and get to grade faster and in fewer passes than ever before.

The AccuGrade System can significantly improve the productivity and accuracy of grading equipment – by as much as 50% over conventional methods. Used primarily for finishing grading, the system is easy to learn. With minimal training, even inexperienced operators are able to get up to speed in no time at all.

The AccuGrade Laser Grade Control System is designed for a wide range of construction earthwork applications requiring tight tolerances and high production rates. Laser grade control is so accurate in fact, that in many cases these systems are required in project specifications or by general contractors in the construction industry. Field-proven and versatile, the dual laser system is ideal for fine grading of sites with flat, single or dual slope surfaces, such as industrial, commercial and residential building sites.